Explore Our 3D Printing Services

Our Services

What We Offer

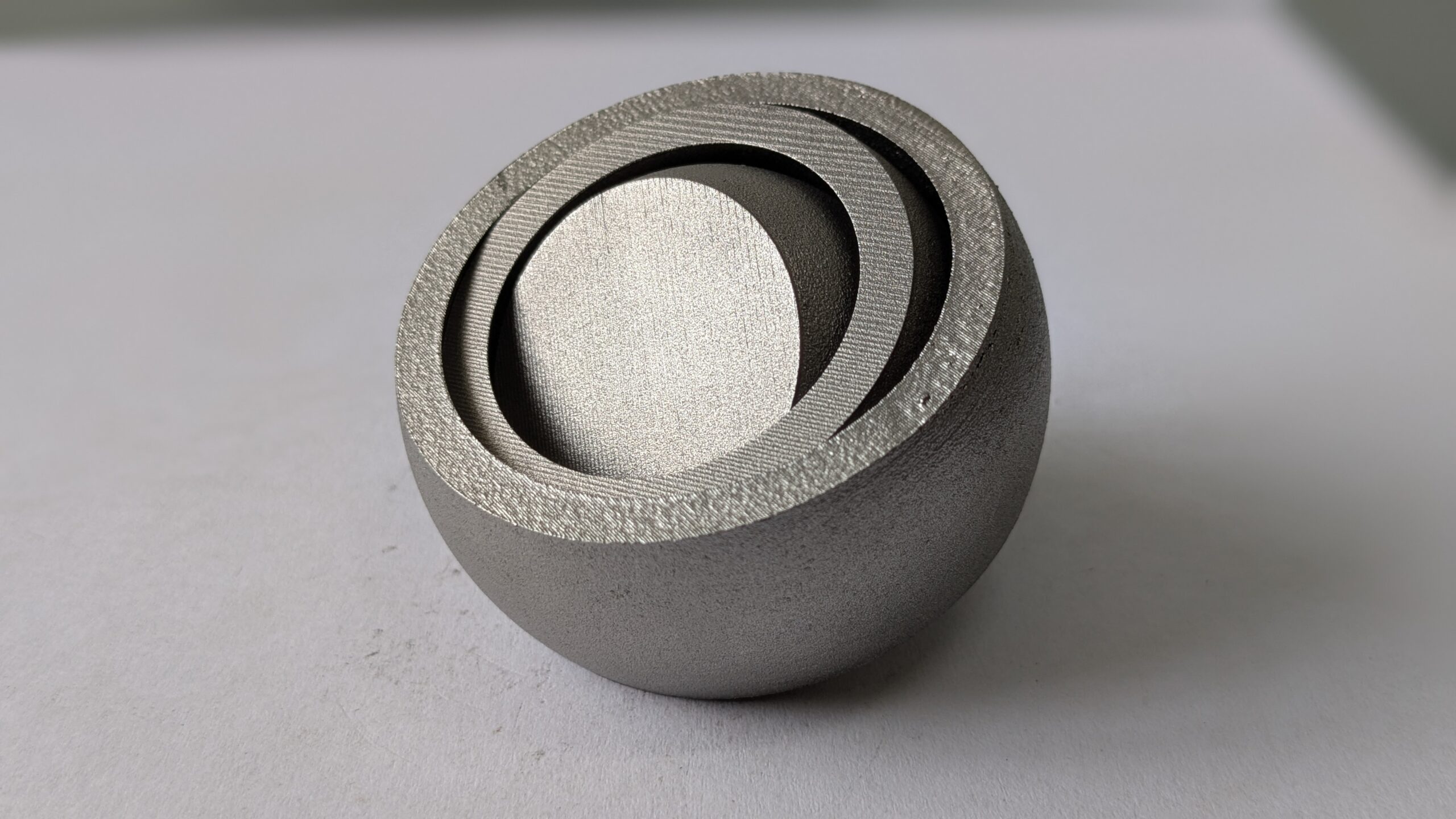

Looking for high-quality 3D printing solutions? At Francis Klein Aerospace Equipments, we specialize in metal, polymer, and ceramic additive manufacturing, catering to a diverse range of industries. Whether you require rapid prototyping, low-volume production, or complex industrial applications, our services ensure precision, reliability, and cost-efficiency.

With state-of-the-art technology, a broad selection of materials, and deep industry expertise, we help transform your concepts into reality. Whether you’re developing new products, refining existing designs, or pushing the limits of manufacturing innovation, we guarantee high-quality execution and on-time delivery.

Our Process: From Idea to Execution

At Francis Klein Aerospace Equipments, we ensure a seamless transition to 3D printing, helping you integrate this transformative technology into your production workflow with ease.

1. Understanding Your Needs

Our process begins with a thorough analysis of your application, material requirements, and production goals. We assess:

- Whether you need prototyping, tooling, or end-use parts

- Your material, precision, and performance requirements

- How 3D printing can enhance and optimize your existing production methods

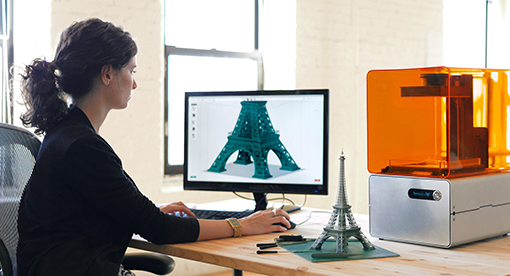

2. Choosing the Right Technology

Based on your requirements, we recommend the most suitable 3D printing solutions, ensuring the best fit for your project. This includes:

- Selecting the appropriate polymer, metal, or ceramic 3D printing technology

- Identifying the best materials, from plastics and composites to advanced metal powders

- Integrating software and workflow solutions for seamless manufacturing

2. Choosing the Right Technology

Based on your requirements, we recommend the most suitable 3D printing solutions, ensuring the best fit for your project. This includes:

- Selecting the appropriate polymer, metal, or ceramic 3D printing technology

- Identifying the best materials, from plastics and composites to advanced metal powders

- Integrating software and workflow solutions for seamless manufacturing

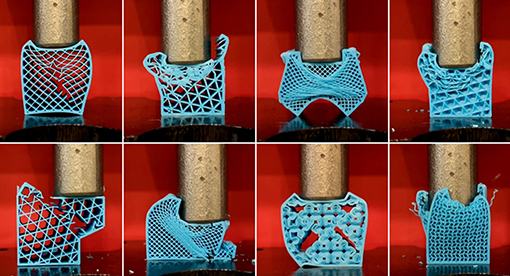

3. Testing & Validation

Before full-scale implementation, we conduct rigorous testing to ensure your project meets the highest standards of quality and performance. This stage includes:

- Prototyping trials and process optimization

- Mechanical property validation for strength, durability, and functionality

- Cost and time analysis compared to traditional manufacturing methods

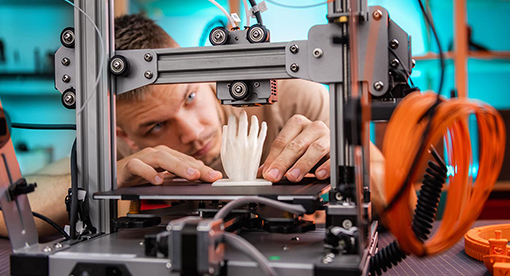

4. Full-Scale Implementation

Once the process is optimized, we provide complete support to help you implement 3D printing into your operations. Our services include:

- Setting up in-house 3D printing, including installation, training, and maintenance

- On-demand 3D printing services for companies that prefer outsourcing rather than full investment

Ongoing support, including software assistance, spare parts supply, and process optimization

4. Full-Scale Implementation

Once the process is optimized, we provide complete support to help you implement 3D printing into your operations. Our services include:

- Setting up in-house 3D printing, including installation, training, and maintenance

- On-demand 3D printing services for companies that prefer outsourcing rather than full investment

- Ongoing support, including software assistance, spare parts supply, and process optimization

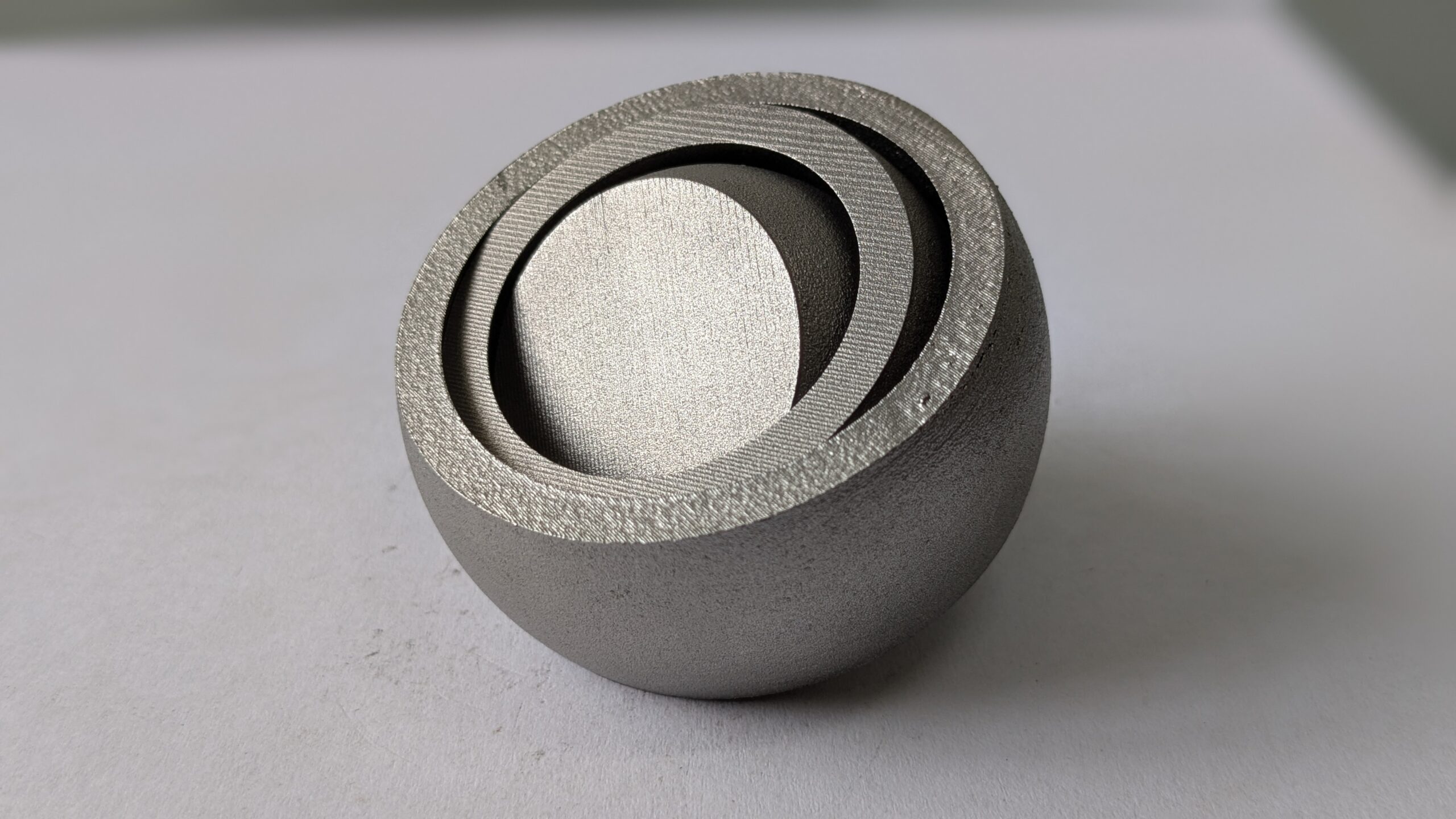

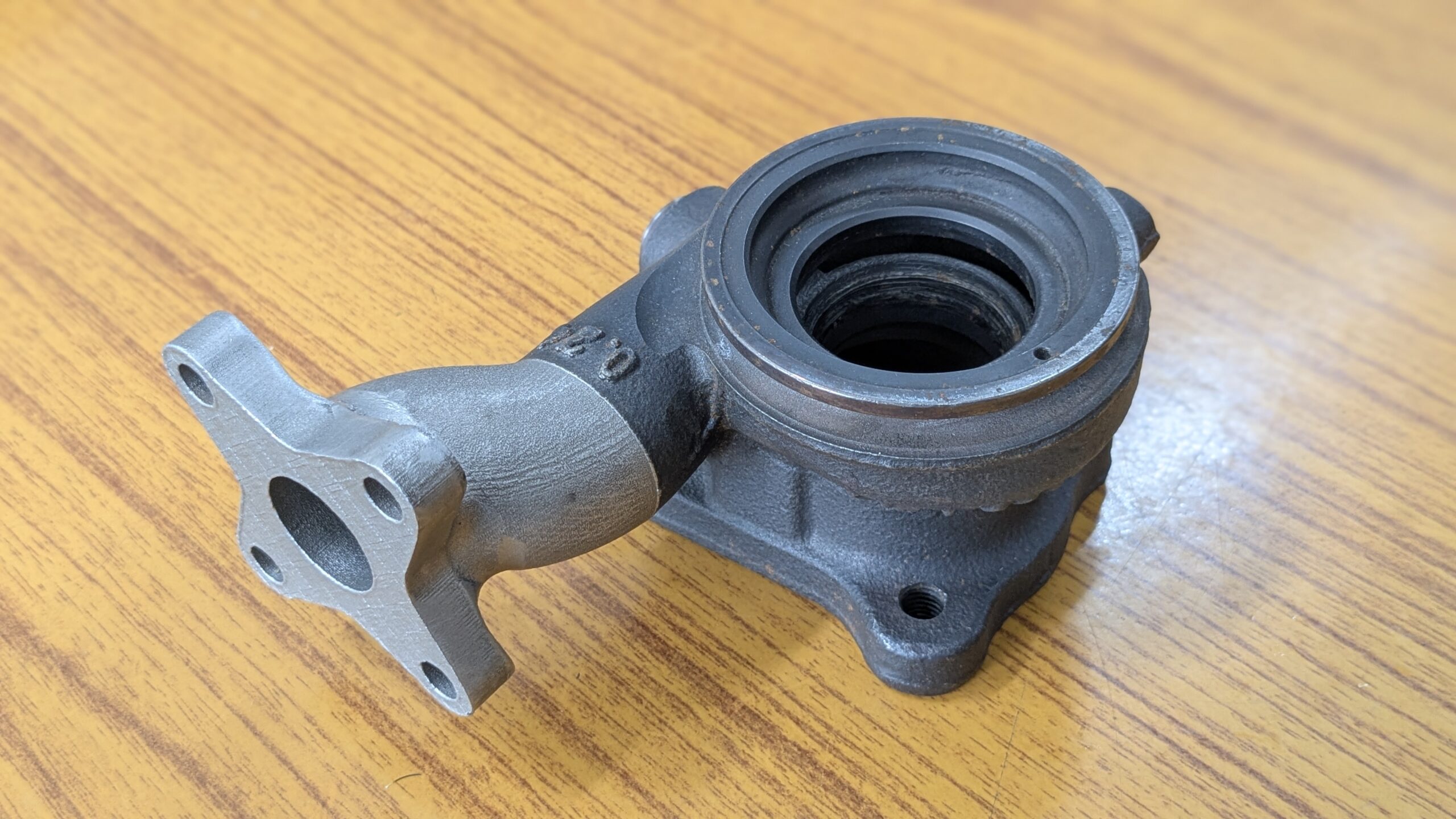

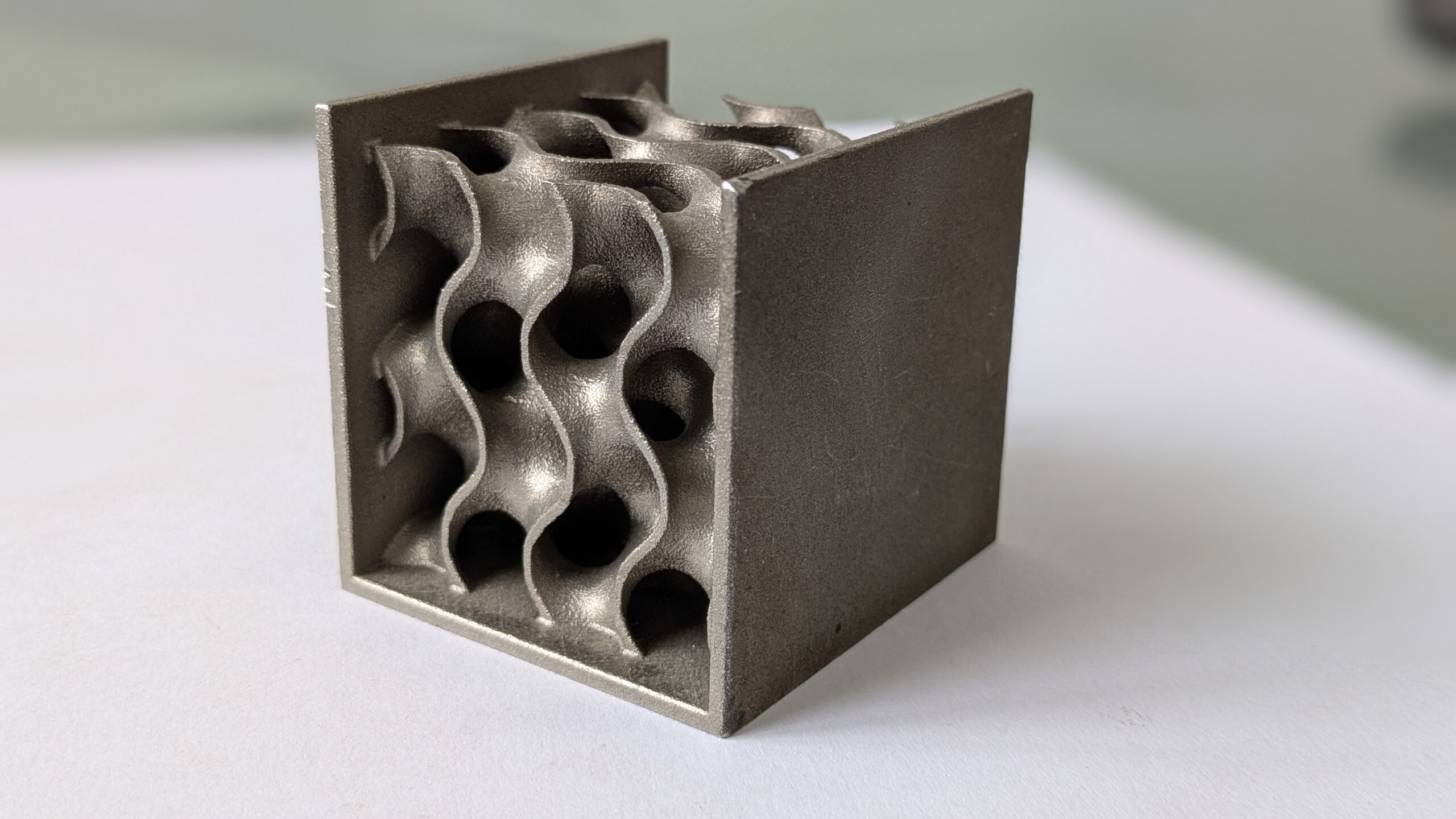

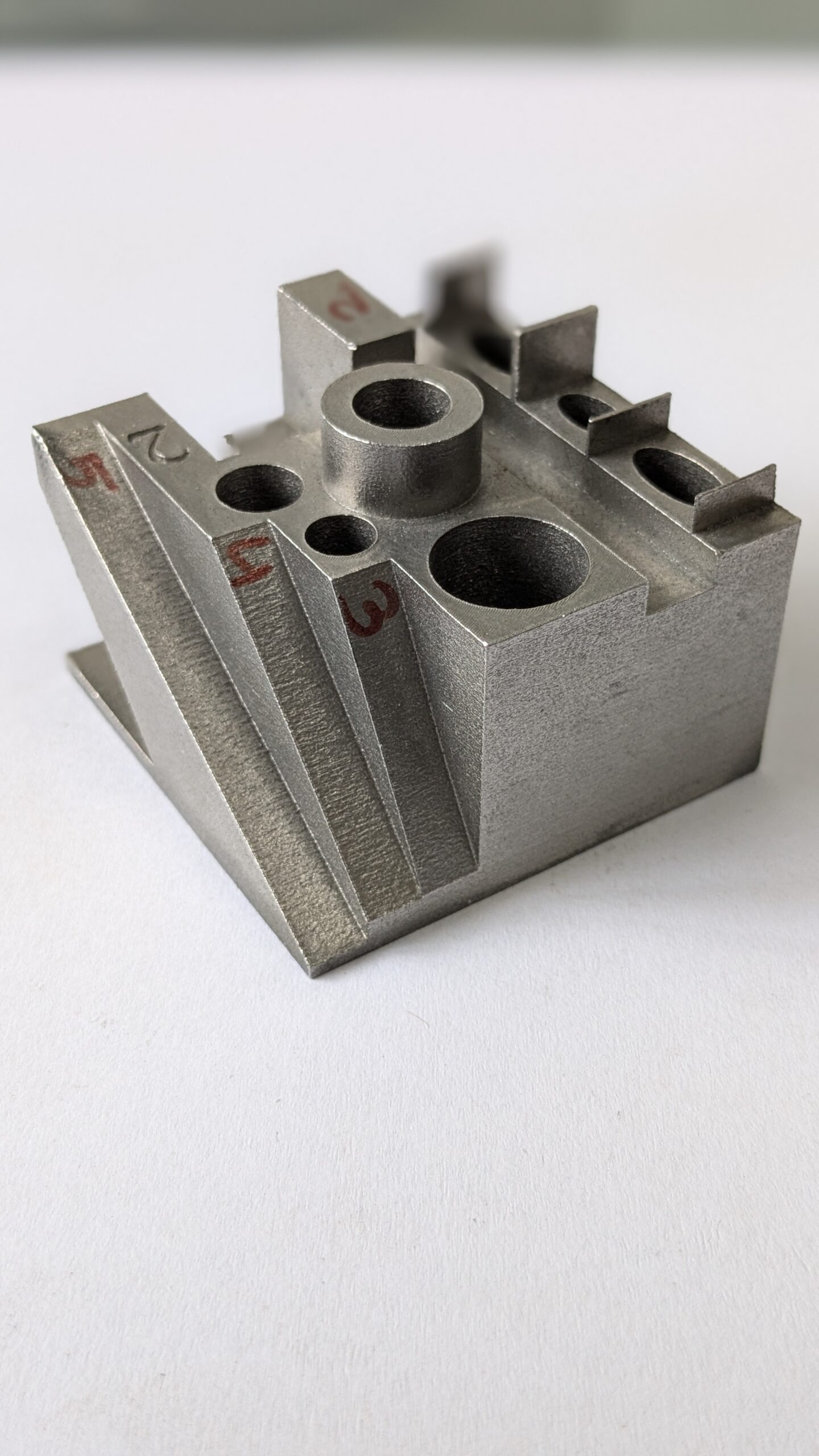

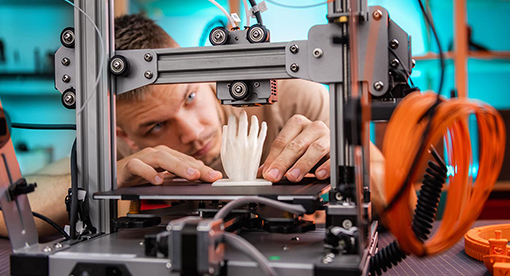

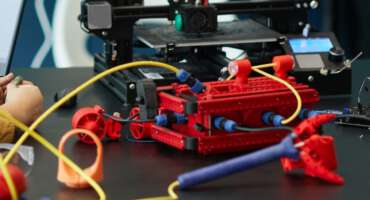

Gallery

Our Gallery